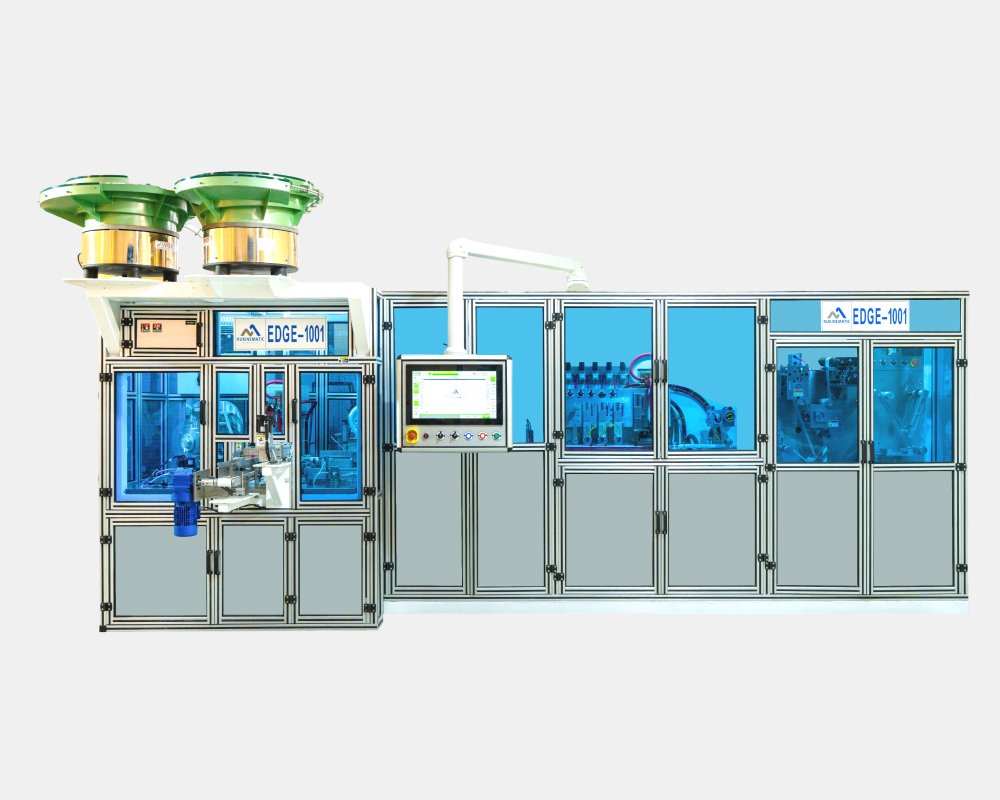

EDGE - 1001

The EDGE-1001 | Automated Laminated Tube Making Machine is a high-capacity system engineered for efficient and precise production of Aluminium Barrier Laminate (ABL) tubes. Designed to meet the rigorous standards of pharmaceutical and cosmetic packaging, it ensures seamless operation from laminate unwinding to body formation and tube heading.

Watch It Work

Machine Specification:

| Machine Speed | 80 Tubes Per Minute |

| Laminate Type | Aluminium based barrier (220-275 Microns) |

| Tube Diameter | Ø 16 -28 MM |

| Tube Length | 60 - 200 MM |

| Max. Unwinder Roll Diameter | 500 MM |

| Top Seal Foil Width | 25-28 MM |

| Capping Options | Standy Cap, Conical Cap, Flip top Cap |

| Shoulder Head | Corresponding to the current market standards |

| Seam Welding | High Frequency Induction Type |

| Shoulder Welding | High Frequency Induction Type |

Technical Specifications

This advanced system is engineered with state-of-the-art technology and can be broadly divided into three major processing sections:

EDGE-1001: Core Functional Overview

Laminate Reel Uncoiling

The Laminate Reel Uncoiling system features a precision-controlled reel unwinding mechanism with encoder-based motion control for consistent tension and accurate feed, handling rolls up to 500 mm and 1,000 meters of material. It includes an integrated splice table with manual brakes and alarm alerts for efficient and safe reel changeover. Ultrasonic and servo-based web alignment stabilizes laminate flow, followed by precision blades that trim edges for accurate sizing. Pressure nipping and rollers ensure smooth material feed, while encoder-driven tension arms synchronize with machine speed to maintain optimal laminate flow at constant web tension.

Body Forming

The laminate is precisely fed by body-pulling rubber belts into the forming section, where guiding forks, rollers, and overlapping wheels wrap it around a body maker shaft to create a cylindrical shape. The induction welding process melts the internal aluminium layer, forming a strong and continuous side seam. Cutting is performed by a servo encoder–controlled flying shear cutter with I-Mark registration, ensuring artwork-aligned precision.

Tube Heading

The heading and capping operations are performed on an indexing rotary table with twelve mandrels, each moving in 30° increments for sequential processing. Key operations include shoulder loading, body loading, induction shoulder welding, top sealing, capping, and tube ejection. This synchronized system ensures high throughput, precise alignment, and leak-proof sealing in a fully automated setup.

Framing Safety Equipment

Machine is completely guarded with multiple doors and operational shutters for easy access to the operator for the operations of machine with adequate safety form external dust and debris. Maintaining hygiene as per pharmaceutical norms required by the industry.

Want to Know More About This Product?

Choose your preferred way to connect with us