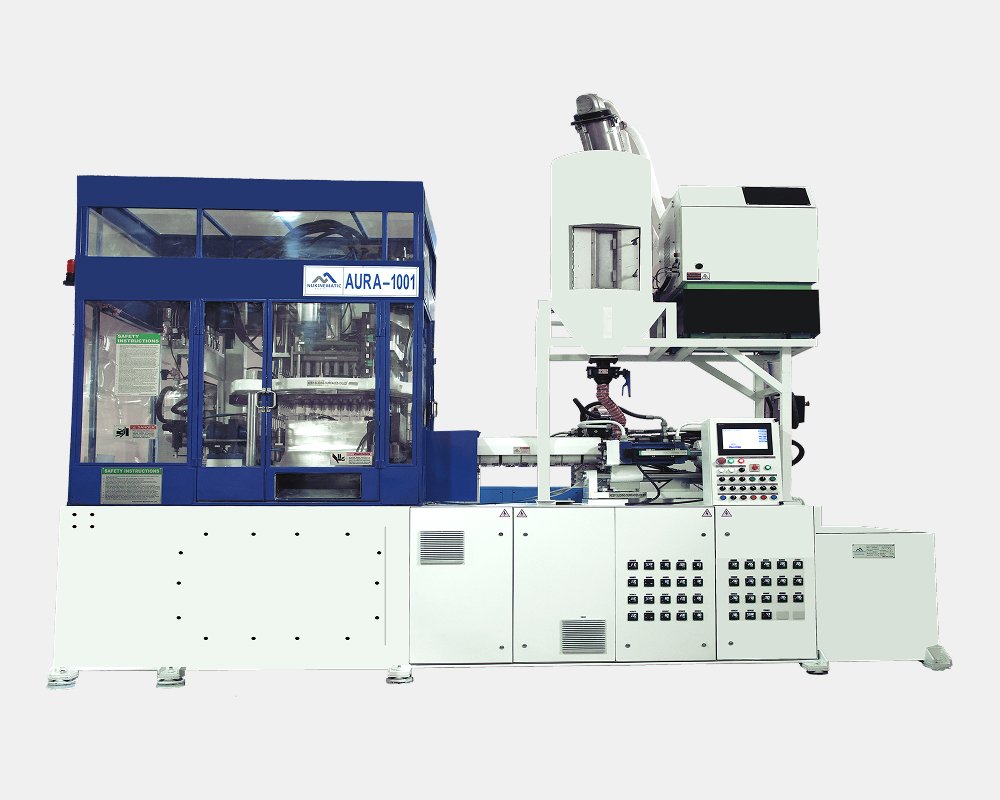

Aura - 1001

The AURA-1001 | Single-Stage Blow Moulding Machine is a fully automated system that combines injection moulding, preform conditioning, and blow moulding into a single streamlined process. Designed for touch-free and contamination-free production, it ensures superior bottle quality, clarity, and dimensional accuracy with minimal energy consumption.

Watch it Work

Machine Specification:

| Machine tonnage | ~20Tons |

| Compatible Materials | PET & PP |

| Machine type | Injection Strech Blow moulding Machine |

| Cavitation | 1- 10 Bottle |

| Injection unit | 45mm screw dia |

| Injection capacity | 286 cm³ /shot |

| Maximum Neck Diameter | ɸ85mm |

| Maximum bottle dia | ɸ125mm |

| Maximum bottle height | 300mm |

| Machine Dimensions | 4500 x 1500 x 3200 |

| Machine Weight | 6500 kgs |

Technical Specifications

This advanced system is engineered with state-of-the-art technology and can be broadly divided into three major processing sections:

AURA-1001 Functional Highlights

Injection Unit

The ISBM process begins with a high-performance injection unit ensuring precise thermal and material control. Preheated resin passes through a precision screw barrel with PID-controlled heating zones for uniform melt and minimal degradation. The hot runner system maintains consistent flow to the injection mould, while a shut-off nozzle ensures accurate shot volume and repeatable preform quality.

Preform Moulding

In the AURA–1001 ISBM machine, preform moulding is executed through a high-precision injection process using an in-house designed mould made from premium materials for durability and accuracy. Each cavity features PID-controlled heating for precise temperature regulation and efficient resin flow. The result is uniform, high-quality preforms with excellent symmetry and minimal material waste.

Preform Conditioning

The AURA-1001 | Single-Stage Blow Moulding Machine is a fully automated system that combines injection moulding, preform conditioning, and blow moulding into a single streamlined process. Designed for touch-free and contamination-free production, it ensures superior bottle quality, clarity, and dimensional accuracy with minimal energy consumption.

Preform Blowing

Once conditioned, preforms undergo stretch blow moulding using high-pressure air within a precision-engineered blow mould. Powered by high-performance hydraulic cylinders, the mould ensures secure clamping, consistent wall uniformity, and superior bottle clarity and strength, supporting customized bottle geometries and nomenclature.

Rotary Table

All processes are synchronized on a central rotary indexing table driven by a high-torque servo-geared motor. Its servo-hydraulic actuation system delivers precise, energy-efficient movement, while real-time monitoring sensors track preform positioning and motion dynamics—ensuring low cycle times, high productivity, and operational reliability.

Bottle Ejection

Finished bottles are released through a precision ejector mechanism using actuated rods for smooth discharge. Integrated real-time sensors ensure no bottle remains in the mould, enhancing reliability and minimizing downtime. The modular ejector design allows rapid changeovers for varied production needs.

Framing & Safety Equipment

The machine is fully enclosed with multiple guarded doors and shutters, maintaining operator safety and protecting against dust and debris. Its design adheres to pharmaceutical hygiene standards, ensuring a clean and controlled production environment.

Want to Know More About This Product?

Choose your preferred way to connect with us